Mould design and construction

Bellucci Stampi

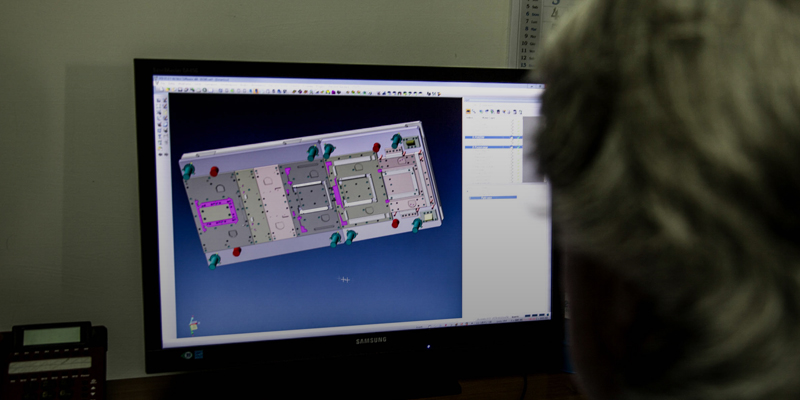

Bellucci Stampi is a subsidiary of Stampaggi Castelfidardo, and has been operating since 1978 in the design and construction of sheet metal shearing and deep drawing. Bellucci Stampi also produces multi-component moulds. The mould design takes place using the latest-generation 3D software.

Bellucci Stampi is a subsidiary of Stampaggi Castelfidardo, and has been operating since 1978 in the design and construction of sheet metal shearing and deep drawing. Bellucci Stampi also produces multi-component moulds. The mould design takes place using the latest-generation 3D software.

Bellucci Stampi designs and builds the moulds used in the sheet metal cold moulding both for the parent company Stampaggi Castelfidardo and for other customers. The design is carried out based on a solid experience over the years using the latest-generation 3D software.

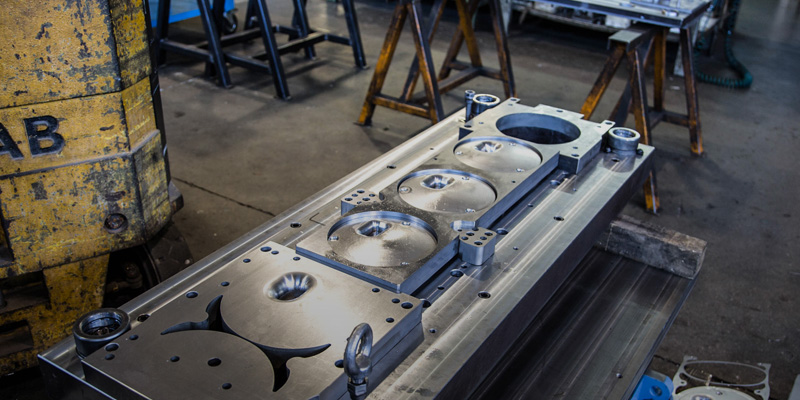

Bellucci Stampi can produce punching dies from small to medium/large sizes (1200×2500), step moulds with built-in tappers, block moulds, rework and deep drawing moulds. In recent years Bellucci has also gained experience in the construction of multi-component moulds, i.e. assembly of several parts within the same mould.

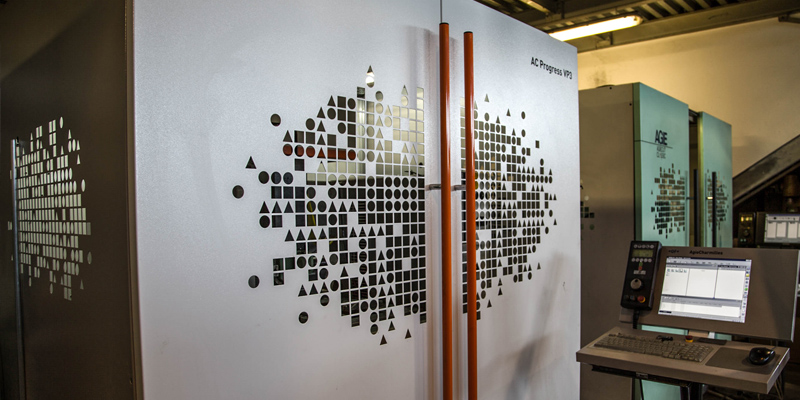

Our workshop is equipped with 3 three-axis CNC milling machines one of which is a fixed bench and 2 are latest-generation CNC milling machines, 4 wire EDM machine (AGIE), 1 drilling machine for high-tempered thicknesses, 3 level grinders, 2 presses for testing the finished mould, and all other equipment for manual tasks.

We offer our customers a complete turnkey service, from the study of the prototype to the realisation of the mould and the subsequent production of the semi-finished product.